What we do

Precision Plastic Extrusions & LED Solutions – Engineered for Global Industries——Your Trusted Partner for High-Performance Extruded Profiles Since 1993

Dachang Plastic Hardware: Precision Extrusion Solutions for Global Industries

Specializing in custom-engineered plastic extrusion profiles, Dachang Plastic Hardware Processing Factory serves diverse sectors with high-performance solutions. Leveraging advanced extrusion technology and expertise in 12+ engineering plastics (including PVC, PP, PC, ABS, and PMMA), Dachang’s products excel in demanding environments where durability, optical clarity, and environmental resilience are critical.

Spreading Plastic Extrusion Industry Insights, Creating Value for Custom Profile Businesses

COMPANY as a shot blasting machine manufacturer has participated in several International and National Standards in the setting and has many invention patents. All the equipment has obtained CE and TUV certifications.

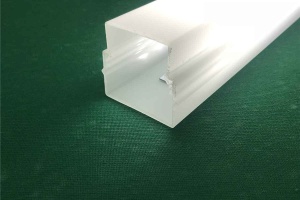

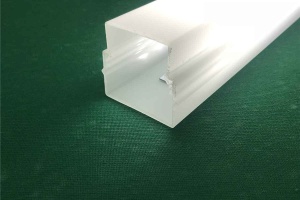

In the production of LED light strip diffusers, precision plastic extrusion technology is one of the core links, involving various issues such as material se……

LED strip diffusers may encounter problems such as uneven diffusion, insufficient light transmittance, and poor weather resistance during use, which can be sp……

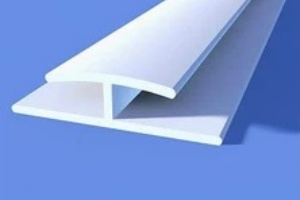

As important components in industrial and civil fields, large plastic profiles have their product quality and performance directly influenced by the precision……

Contact Us

Subscribe

Sign up for the latest product and event news